Create a resilient database

through integrated evaluations. For more competitiveness.

You probably know the term CIP – Continuous Improvement Process. The objective in this process is the steady improvement of one’s own competitiveness in multiple small steps. Our objective is to provide you with the right tools. Because it’s not about monitoring, but rather, to measure one’s own performance and to set relevant parameters (KPIs). This is not possible without reliable data foundation. This is created by using our defects management system just in the context of the operational activity itself.

By means of the integrated analyses of our defects management solution, you can visualize characteristic values and obtain the foundation you need to optimize your processes.

Transparent defect tracing

Company-wide for all projects

In order to optimize your own processes, you need have a eye on the big picture. To do this, it is necessary to use a solution that includes all projects.

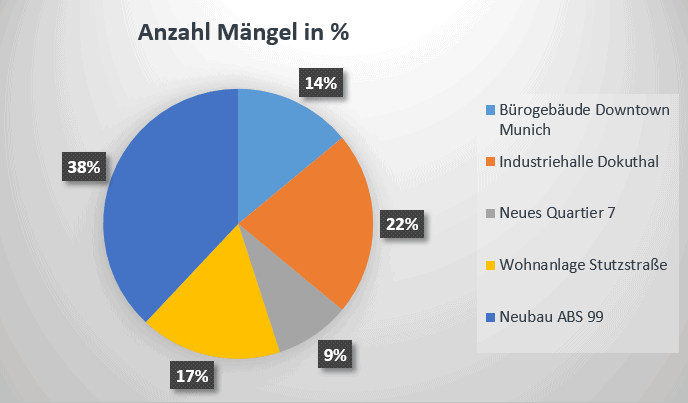

With mydocma MM you can, as an example, create the following analyses in an instant:

- Number of open defects in a project

- Number of errors due in a project

- Number of critical errors per project

- Average handling time

Desired evaluation

So that no question remains open

You yourself determine the parameters you would like to use for the analysis in mydocma MM. In addition to trades, all other attributes are available for analytical purposes. Make reliable statements:

- Number of defects by trade

- Number of defects by company

- Division of building defects by components, floors or rooms

- Number of critical defects

- Number of defects that are overdue